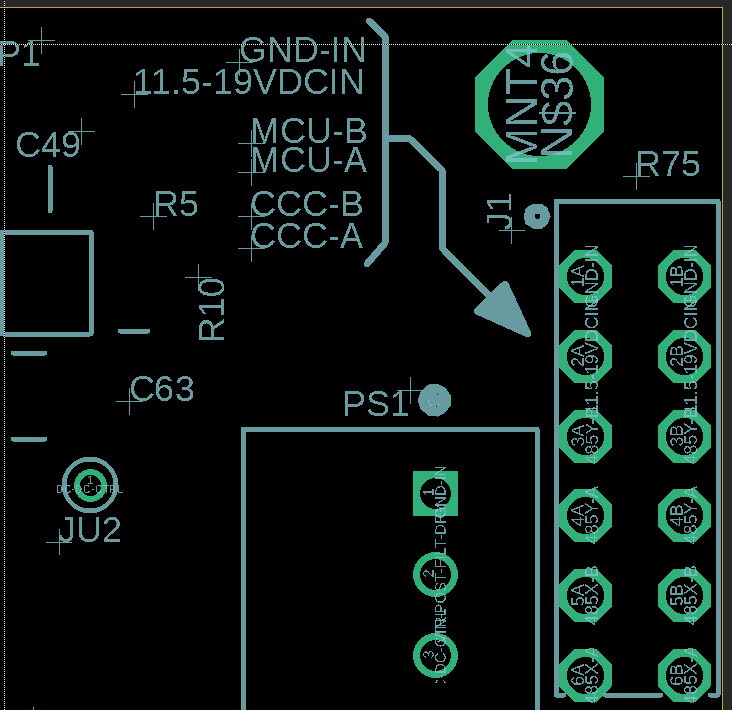

The HDL-0104-RS104 is a prototype 4-channel rapid scan ultrasonics-for-NDT board for embedded applications that includes RS-485 communications, additional circuit protection components, and an isolated design. This article covers the basics of wire to board connections.

The default assembly variant / build for this prototype populates the main wire-to-board connector with a wire push-in style terminal block connector. You may wish to remove this for direct wire-to-pad solder connection with appropriate strain relief.

| Position | Name/Function | Notes |

| 1 | Ground (GND-IN)/System Power Supply Ground Input | TBD – A few configuration options. Nominally isolated from main board ground by design. |

| 2 | Positive DC Input Voltage | 11.5VDC to 19VDC is the usable DC voltage input range. Check (estimate) actual voltage at the terminal block for a cable resistance specification at the cable length and operating current to be used. |

| 3 | MCU RS485-B Signal | Control RS-485 B signal (e.g. Twisted pair #1) |

| 4 | MCU RS485-A Signal | Control RS-485 A signal (e.g. Twisted pair #1) |

| 5 | CCC RS485-B Signal | Data RS-485 B signal (e.g. Twisted pair #2) |

| 6 | CCC RS485-A Signal | Data RS-485 A signal (e.g. Twisted pair #2) |

Cat6 at 23-awg with 4-pairs and shielded may be a good starting point for your testing. Slightly more copper for less resistance for power delivery, better noise cancellation and protection for noisier environments. You could terminate the shield at one end, the acquisition and data processing end with the RS-485 to USB (serial/UART) conversion end of the system.

There is also control cable, marked and color-coded for particular applications, that might better suit the application. For example, some control cable (see eg Belden, still off the shelf), may include larger diameter copper and twisted pairs (or for its twisted pair) with a particular frequency rating that still far exceeds the needs here. It may not be necessary, or may be useful. Discussion and example(s) continue below …

Prototype testing used a basic Cat5e [24/4 (4 twisted pairs)] cable of 350-feet in length. Two twisted pairs for communications as noted in the figure and table here in this article, and then one or two twisted pairs for the power supply. However, this was for a basic level of testing in a lab bench type of setting (versus noisier industrial).

Note that 24-awg cable has a relatively high resistance for a power supply line over long distances. Hence the idea of using perhaps one pair for positive DC supply, and the last pair for ground input reference.

The comparable 8-channel rapid scan USB board draws a typical steady 260mA at 5VDC supply during active acquisition data streaming, as an example.

Assistance with you specific use-case and system is available, including calculated estimates of power and voltage envelopes. Actually board current draw is not yet measured, and will be assessed once the hardware is ready for testing.

One example calculation: 23 awg (Cat6) at 350-feet, 4-pair. Board drawing 300mA. Source voltage at 12VDC. 23-awg at approximately 20 milliOhms/ft => 7 Ohms over 350 feet. Using that old friend: V = I x R: 0.3A x 7 Ohms = 2.1 Volts of voltage drop over a single wire. So voltage at the board input becomes nominally 12VDC – 2.1 = 9.9VDC input. Over two of the wires (using two pairs for power/ground): We could estimate about half of the resistance. You could also measure the resistance of your cable length. So that means about 1.1VDC voltage drop, getting to about 10.9VDC input at the board itself.

There are several factors to consider on the board, including component population option, so the actual input voltage range may be greater. Other factors: Current draw may be less (or more). You may have a power supply with a nominal output rating but with some available adjustment (often the case) to achieve the required input voltage to the board. Please be in touch for your specific application and we can select the right solution, or range of solutions. There is flexibility.